Talking better product launch and allocation decisions with Ferrero USA

The global confectioner mitigates waste, improves service levels and controls costs by connecting digital supply chain visibility with POS analytics.

Keep readingIf you’re stuck running from one fire to another, you’re not alone.

And if you read our recent white paper Why the chaos? Exposing the gap between planning and execution, you understand the disconnects across people, processes and systems that cause it. But what to do about it?

First thing to note: you don’t have to figure all the details out before you start down the road. In fact, it’s best to work iteratively, allowing technology, people, organizations and processes to influence each other.

Begin like this:

What does it take to successfully enable this approach? We’ve summarized some must-haves below. For the complete details, download the full guide, Taming the chaos: Steps to bridge the planning-execution gap.

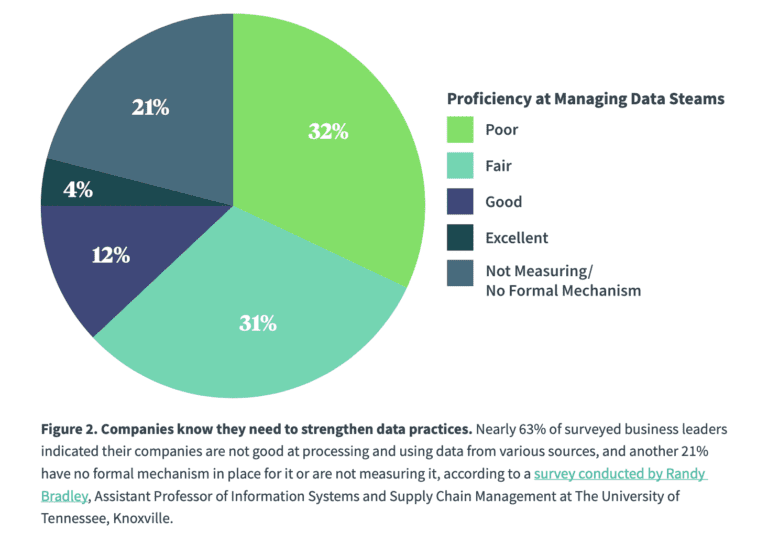

Escaping from eternal crisis mode means preventing issues from ever falling into the gap between planning and execution. To bring them to the surface so they can be addressed earlier, data from multiple sources (including your planning tools, ERP, retailers, and other partners) must be harnessed and turned into useful information for decision support. You should:

These steps make your data useful and actionable – and put you ahead of the pack when it comes to highlighting problems when reality doesn’t follow plans.

Then you can formulate rules for prioritizing issues. If done well, your tools can conduct constant and autonomous triage without the risk of human error. They can help weed out problems that will go away by themselves and elevate to your attention those issues that warrant further investigation and action.

With the best data from the right sources, available and usable for all stakeholders, your processes and organizations can begin to break free from traditional silos. Mapping your supply chain, calculating KPIs and prioritizing issues are a further step toward a healthy supply chain. You’re on your way to constructing the needed bridge between plan and execution.

The most important result isn’t just supply visibility though; it’s what your teams do with it. With a shared single source of truth, they can avoid wasting time going back and forth over data and what’s most important – and get to the task at hand. When unbiased tools provide a context for the conversation (including upstream and downstream implications), teams can quickly work together to form a solution. They can explore the same up-to-date information, digging into it with their own expertise to inform a robust collaboration.

Some have said technology will kill supply chain management, but we believe supply chain technology empowers better human decision-making. An algorithm can’t weigh the strategic prospects of a new retailer or make a call to a valued customer. But it can examine floods of intricately linked data, harmonize that data for human consumption and render it for better human decisions.

And when that happens, your supply chain finally matures from never-ending, chaotic firefighting into a resilient, proactive stance that benefits the entire organization. In fact, a supply chain control tower solution with end-to-end supply chain visibility can result in up to:

Get into the details – like how to make your data more relevant and more meaningful for your supply chain. For the actionable steps you can start taking today, download Taming the chaos: Steps to bridge the planning-execution gap.

The global confectioner mitigates waste, improves service levels and controls costs by connecting digital supply chain visibility with POS analytics.

Keep readingUnderstand how gaps between systems, teams and processes are keeping you constantly firefighting and hurting your supply chain resilience

Keep readingInventory Intelligence completes your digital supply chain transformation with a real-time control tower to bridge the gap between planning and execution.

Keep reading